The B&M Superchief siren. We at Horn & Whistle refer to this as the "Rolls-Royce" of vehicle sirens. It is first of all an extremely efficient siren, consuming about half the power as its closest competing siren and yet at 100 feet and more it is louder. How is this possible? It is due in part to the front section of the siren which is similar to the nacelle of a jet engine. It is also related to the design of the impeller blades and the close tolerance between the impeller and the stator. These factors combine to produce a tone which has very good long-distance propagation properties.

B&M Superchief siren mounted on a so-called "wing-platter" light bar.

This siren is entirely made in the USA, and all parts of the siren are, with the exception of the motor field coils [which are made in Canada] likewise made here in the USA. Machining is extremely accurate; even the motor housing is machined so that it fits accurately in the clamp ring that secures the siren pedestal. The front and rear covers are made of highly polished stainless steel, and likewise the all-important siren stator is stainless, so it won't get all corroded and pitted over time especially if you use the siren in a part of the country where winters are severe and the highway departments lay down liberal amounts of road salt.

Here are several other pictures which show the siren in more detail, including several showing its internal parts. This shows the high quality workmanship throughout the entire machine.

B&M sirens are so efficient aerodynamically that they must be equipped with a siren brake, whereas brakes are optional on other sirens. But the forward motion of the vehicle will move enough air through the siren that the rotor will start to spin by turbine action and generate some tone even without applying power to the siren motor. Therefore, in B&M sirens, the brake is applied by a spring and retracted by the brake solenoid during operation which is the opposite action of siren brake systems in other sirens.

Another view of a B&M Superchief Siren

B&M sirens are coaster sirens which means that when you cut the power to the siren motor, the siren rotor will continue to spin independently of the motor shaft on its own separate ball bearings and gradually decelerate over a longer period of time than it would if the coasting feature was not used. This greatly reduces the average power demand made by the siren because for long intervals of time the siren is producing tone without consuming any electric power from the vehicle's electrical system.

Over time, repeated usage of the siren tends to wear out or deform coaster clutches in some sirens, but the B&M siren coasting clutch is much larger than those used in other sirens and it is made entirely of hardened steel parts. It does not depend on friction pads or discs that can wear out, and it is built to withstand the repeated mechanical shocks that occur when the motor accelerates the high-inertia siren rotor.

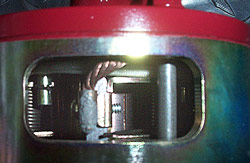

the second picture shows you the Superchief with the back cover removed. Note how the base pedestal is securely clamped to the motor housing which is very accurately machined for a good fit. You can also see the removable band that covers the brush inspection openings. Also, at approximately the eleven o'clock position you can see the brake solenoid which retracts the brake when the siren is to be used. When correctly installed on a vehicle, the switch to release the break also enables the main siren relay, thus the siren can't be unintentionally operated with the brake engaged. Most of the other pictures are self explanatory and show the siren rotor installed and also a look at the rotor itself and the stator.

Clearance between the rotor and stator is very accurately maintained at about 0.010 inch, which is important for good sound development; sloppiness here results in severe loss of upper harmonics in the generated sound which translates to a less-penetrating signal at all rotor speeds.

The picture at the lower left shows the clutch hub which is securely keyed to the shaft. Also note in this picture that near the end of the shaft where the threads are, there is a small hole. This is for the insertion of a cotter pin. The rotor is secured to the shaft by a so-called castle nut and the cotter pin fits into one of the slots on the castle nut which positively prevents the nut from ever backing off and not securing the rotor correctly.

The entire stator is machined from stainless steel which gives this siren superior corrosion resistance, so that it will retain its excellent appearance even in bad weather conditions. Likewise, the dome-shaped rotor tip, which encloses the castle nut and cotter pin is also made from stainless.

If you look closely at the picture of the siren rotor, you will note that closer to the center, the blades are considerably angled, but then they become more-nearly perpendicular at the rotor ports. Backward inclined blades make the rotor more efficient as a centrifugal blower, which is how the siren gets its airflow to make sound. But blading that is more nearly perpendicular is conducive to better tone. The designers of the Superchief have carefully incorporated this important quality into the rotor design which means that you get powerful siren tone, but do so with a smaller power demand.

The price of a new Superchief siren is $2133.

If you would like more information on the B&M Superchief, please use this simple, no obligation form that is below the pictures.

View of siren rotor.

General view of motor and brake solenoid.

Another view of rotor, coaster clutch inside center dome.

Closeup of motor, showing one brushholder and commutator.

Siren rotor,note angled radial blades to increase airflow for louder sound.

Stator. Note coaster clutch cam on shaft.